Why Custom with Us

Six core advantages that make us your ideal custom ceramic manufacturing partner

Custom Shape Molding

Advanced ceramic molding technology with precision engineering. Create unique product forms tailored to your brand concept. Stand out in the market with distinctive ceramic shapes that reflect your brand identity.

Logo & Color Design

Professional ceramic printing and custom glaze color matching. Personalize ceramics with your brand colors and professional logo printing. Build stronger brand recognition and customer loyalty through cohesive brand presentation.

Tailored Packaging Solutions

Custom packaging design from gift boxes to export cartons. Complete packaging solutions that enhance your brand image. Create memorable unboxing experiences that increase customer satisfaction and repeat purchases.

Strict Quality Control

Comprehensive testing including glaze, hardness, and safety standards. Every customized item undergoes rigorous quality testing before shipment. Ensure consistent quality that protects your brand reputation and reduces returns.

Global OEM Experience

Successfully serving buyers across USA, UK, Australia, and Europe. Proven OEM expertise with international quality standards. Leverage our global experience to ensure your products meet local market requirements.

Reliable Lead Time

Streamlined production and supply chain management systems. Guaranteed on-time delivery through efficient manufacturing processes. Plan your inventory and launches confidently with predictable delivery schedules.

Ready to experience the full potential of custom ceramic manufacturing?

Explore Custom OptionsPain Points & Solutions

We understand your challenges and provide proven solutions for successful custom ceramic projects

❌ Common Buyer Pain Points

Hard to communicate design ideas

Struggling to convey your vision to manufacturers who don't understand your creative concepts.

Color difference after firing

Final products don't match approved samples due to inconsistent glazing processes.

Unpredictable production timeline

Delays in custom orders affecting your product launch and marketing schedules.

High minimum order quantities

Unable to test market demand due to excessive MOQ requirements for custom products.

✅ Our Proven Solutions

3D preview design team

Our design team provides detailed 3D previews and technical drawings for clear communication.

Professional glazing control

Advanced glazing technology with sample confirmation ensures perfect color matching every time.

Structured project timeline

Clear 10-step workflow with milestone tracking keeps your project on schedule and budget.

Flexible custom MOQ

Starting from 1,000 pieces for custom designs, allowing you to test markets cost-effectively.

Let us solve your custom ceramic challenges with our proven expertise

Discuss Your ProjectFeatured Ceramic Products

Explore our premium collection of handcrafted ceramics, designed for quality and elegance

Bestseller

Bestseller

New

New

Popular

Popular

New

New

Bestseller

Bestseller

OEM Workflow

Our proven 10-step process ensures seamless execution from concept to delivery

Inquiry

Send your custom idea, reference photo, or drawing to start your project discussion.

Consultation

Our sales and engineers analyze feasibility, suggest material, glaze, and structure options.

Quotation

Receive a detailed quotation including mold fee, MOQ, and estimated lead time.

Drawing Confirmation

3D or 2D design drawing is created for your approval before mold production begins.

Mold Development

Custom molds are made precisely according to approved drawings for accuracy and consistency.

Sample Production

First samples are produced and finished to verify color, glaze, and overall appearance.

Sample Approval

You confirm the sample quality and authorize mass production after necessary adjustments.

Mass Production

Full-scale production starts with strict in-line quality inspection at every key process.

Final Inspection

Each product is checked under AQL standard and securely packed for international shipping.

Delivery & Support

Products are shipped as scheduled, and our team remains available for post-delivery support.

Experience our systematic approach that guarantees successful custom ceramic projects

Start Your WorkflowSample Development Gallery

Visualize the journey from concept to finished product through our comprehensive sampling process

Clay Prototype Stage

We hand-craft initial prototypes from raw clay, enabling rapid concept validation and form refinement. This approach allows you to test and perfect the basic shape without committing to expensive mold production, giving you the flexibility to explore multiple design iterations and achieve your ideal product form before moving forward.

Mold Development

Our precision mold manufacturing transforms approved designs into production-ready tools with exact dimensional accuracy. This critical stage ensures every piece produced maintains consistent quality and perfect replication of your design, establishing the foundation for reliable mass production that meets your exact specifications every time.

Bisque Firing Test

We conduct initial bisque firing to verify structural integrity and identify any potential issues before glazing. This preliminary firing stage allows us to detect and resolve problems early in the process, saving you time and resources while ensuring the final glazed product achieves optimal strength and durability for your market requirements.

Glazing Process

Our professional glazing application delivers precise color control and superior finish quality through expert color matching techniques. This meticulous process ensures your final products perfectly align with your brand specifications, eliminating color discrepancies and guaranteeing consistent quality that reinforces your brand identity across every piece.

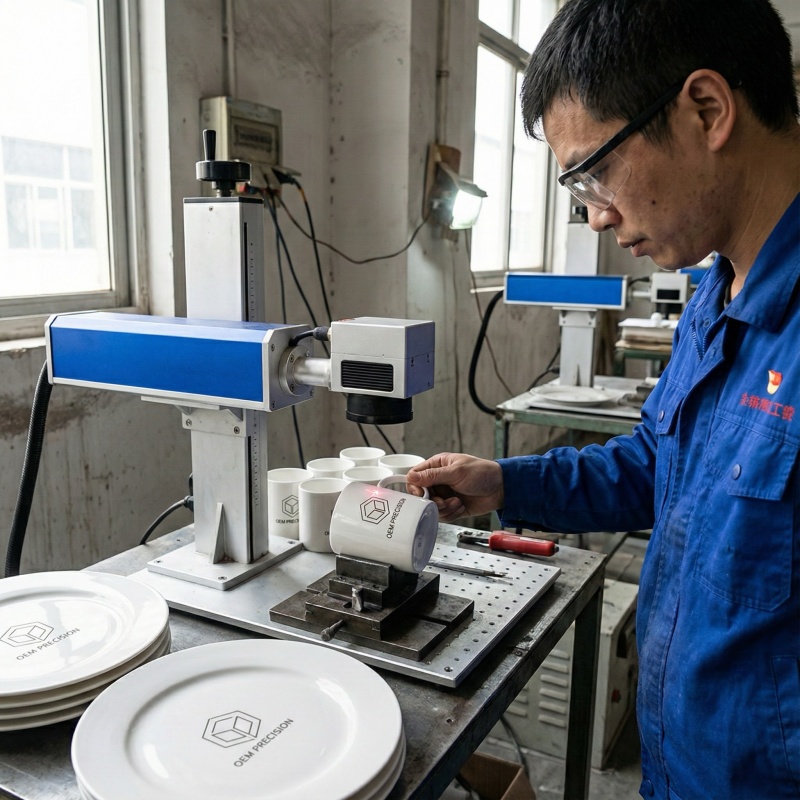

Logo Printing Sample

We create test samples with your custom logo and branding elements using advanced ceramic printing techniques. These samples demonstrate how your brand identity translates onto ceramic surfaces, allowing you to verify placement, color accuracy, and overall visual impact before authorizing full production runs of your branded ceramic products.

Finished Sample

We provide complete production-ready samples with final finish that serve as exact previews of mass production quality. These tangible samples give you absolute confidence in your investment by offering concrete proof that your concept will translate successfully into market-ready products, eliminating uncertainty before you commit to full-scale production.

See your ceramic vision come to life through our proven sampling process

Request Sample DevelopmentLogo Printing Showcase

Multiple professional printing techniques to showcase your brand with elegance and durability

Gold Foil Printing

Premium metallic finish for luxury brand presentation

Hand-painted Design

Artisanal hand-painted logos for unique artistic appeal

Screen Printing

Vibrant colors with excellent durability for high-volume orders

Decal Transfer

Precise detailed graphics with photographic quality reproduction

Embossed Pattern

Raised 3D texture design for sophisticated tactile experience

Laser Engraving

Permanent precision etching for modern minimalist branding

Underglaze Printing

Fade-resistant color sealed beneath glaze for lasting beauty

Reactive Glaze Logo

Organic color variations creating one-of-a-kind brand marks

Transform your brand identity into stunning ceramic artwork that customers will treasure

Explore Printing OptionsColor & Glaze Options

Unlimited color possibilities and professional glaze finishes to match your brand aesthetic

Matte Finish

Elegant non-reflective surface with sophisticated touch

Glossy Finish

High-shine surface that enhances color vibrancy

Reactive Glaze

Unique patterns created through chemical reactions

Gradient Glaze

Smooth color transitions for artistic effects

Create the perfect color story that resonates with your target audience

Request Color MatchingPackaging & Branding

Complete packaging solutions that enhance your brand image and protect your investment

One-Stop Branding Solutions

- Gift Box Design: Premium presentation boxes that create memorable unboxing experiences

- Brown Box Packaging: Cost-effective shipping solutions with custom branding options

- Custom Labels: Professional labeling with your brand information and product details

- Barcode Integration: Retail-ready products with proper inventory tracking systems

- Compliance Marking: All necessary certifications and safety markings for your market

Complete your brand story with packaging that speaks to your customers' hearts

Design Custom PackagingQuality Assurance in Custom Orders

Rigorous testing protocols that eliminate risks and ensure consistent excellence

Glaze Thickness Test

Precise measurement of glaze application uniformity ensures consistent finish quality across all pieces, eliminating quality variations that could damage your brand reputation.

Drop & Thermal Shock Test

Rigorous durability testing under real-world conditions verifies product strength and thermal resistance, ensuring confident product performance that exceeds customer expectations.

FDA / LFGB Compliance

International food safety certification testing provides global market compliance and safety assurance, giving you peace of mind that your products meet the highest safety standards worldwide.

Material Composition Analysis

Advanced laboratory testing verifies raw material purity and composition to ensure consistent quality, durability, and safety in every batch of ceramic products manufactured.

AQL Inspection Standards

Comprehensive quality control using Acceptable Quality Limit protocols ensures each shipment meets international standards, minimizing defects and maintaining your brand's reputation for excellence.

ISO Certified Process

Our ISO-certified manufacturing processes guarantee systematic quality management throughout production, from raw materials to finished products, ensuring reliable and consistent results every time.

Our quality assurance transforms custom manufacturing risks into guaranteed success

View Quality CertificatesFAQ for Customization

Clear answers to your most important custom ceramic manufacturing questions

What's your MOQ for custom designs?

Our minimum order quantity for custom designs starts at 1,000 pieces per design. This allows you to test market demand cost-effectively while maintaining production efficiency. For complex designs requiring new molds, we recommend starting with 2,000 pieces to optimize your investment.

Can I see a pre-production sample?

Absolutely! We provide pre-production samples at every stage - from clay prototype to glazed finish. This includes 3D previews, color matching samples, and final production samples. You won't proceed to mass production until you're completely satisfied with the sample quality.

How long for mold development?

Mold development typically takes 15-25 days depending on design complexity. Simple shapes require 15-18 days, while intricate designs with detailed features may take 20-25 days. We provide regular updates throughout the mold development process.

What's included in the mold fee?

The mold fee covers complete mold development, including design optimization, mold manufacturing, first sample production, and design adjustments. Once paid, the mold belongs to you and can be used for future orders without additional charges.

Do you offer design consultation services?

Yes, our experienced design team provides comprehensive consultation including feasibility analysis, material recommendations, cost optimization suggestions, and design improvements. This service is included free with custom orders to ensure your project's success.

Still have questions? Our custom ceramic experts are ready to help

Ask Your QuestionTestimonials & Partners

Trusted by leading brands worldwide for exceptional custom ceramic manufacturing

Trusted by Leading Brands

Join hundreds of satisfied customers who've transformed their vision into reality

Start Your Success StoryLet's Create Your Next Ceramic Collection Together

From initial sketch to final production, we manage every step of your custom ceramic manufacturing. Our advanced facilities transform your creative concepts into market-ready products with unlimited design possibilities.

Backed by 15+ years of international OEM expertise, we deliver consistent quality across production runs while meeting global export standards. Your unique ceramic designs will command premium prices, build customer loyalty, and elevate your brand above competitors.